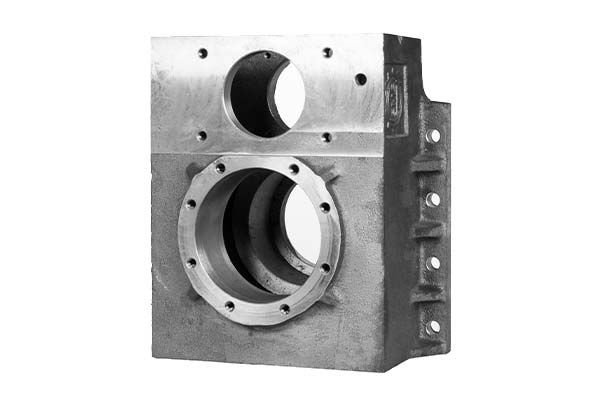

| SMS ALLOYS | |

|---|---|

| Built Up area | 20,000 Sq.ft |

| Installed Capacity | 300 Tonnes/ Annum |

| Installed Weight Limit range | Maximum 300 Kgs a single piece casting |

| Captive power (for 100% power Backup) | 150 Kva Diesel Generator |

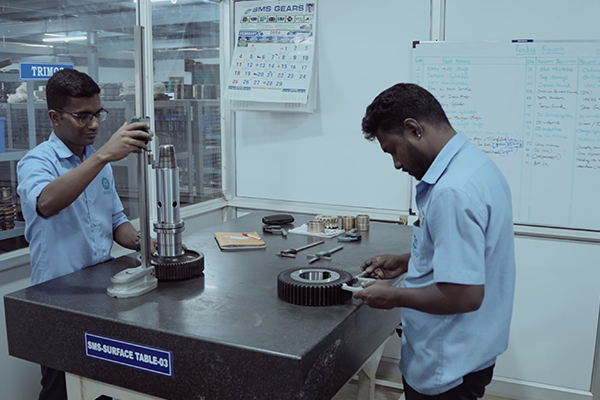

PHYSICAL TESTING

Physical Testing unit comprises of the following equipment calibrated under third party TUV, BVQI, DNV-GL, Lloyds & IBR.

-

Screen – Fine ground glass screen 300 mm x 5 mm with cross lines at 900 Magnification – 10 x Lens

-

Workstage – Size of Top Plate – 350 x170 mm

-

Measuring Traverse XIY axis – 200 x 100 mm

-

Working Area – 245 x 120 mm

-

Load Capacity – 20 Kgs

Max -150 mm

Brinell hardness testing machine with 0-600 BHN range.